Tips on Secure Driveway Edging with Steel

People often ask us about using steel for driveway edging. Steel edging is a popular choice because it is quite discreet and practical when used to divide say a lawn from a driveway.

This is what we know and what we’ve learned from others who’ve done it. There are some key questions to weigh up…

- Will you be driving over the driveway edge by necessity?

- What adds strength to the edge?

- Can I use a Straightcurve for my driveway edge?

Hardline Render

Will you be driving over the driveway edge by necessity?

If your driveway edge will be driven over then our steel edging may not be your best steel edge option. We’d recommend to use a heavier gauge of flatbar steel, say 6 mm thick and 100mm tall. Curving it should be alright as long as you have plenty of leverage and it’s a gentle curve. Did you know the curvature actually gives the edge more strength? Welding the edges together is strongly recommended as they will open up and move if you don’t. Ideally, check with a local structural engineer to ensure you have strong enough footings to hold the edge up as this depends on your soil conditions; the forces pushing on the edge wall are considerable.

If you feel confident that you know what you’re doing, we recommend to dig holes, 50 cm deep, a meter apart and set the edge in concrete with welded on rebar. Sections where you’ll drive across will need additional footings (60 cm between footings).

Understand though that If your expecting cars to traverse the edge maybe your driveway position or size should be reviewed or some strategic ‘barrier’ plantings introduced. You’ll find it easier to have an attractive, well maintained driveway edge (on both sides) if people stay on the driveway as intended!

Driveway Edge

What adds strength to the edge?

A large part of the strength of the driveway edge actually comes from the supporting materials around and beneath it, the firmness of the underlying soil is particularly key. If there are any doubts re the firmness of the underlying base then some method of concrete footing for the pegs or edge is needed.

The steel edge should finish flush with or barely above (advised if retaining loose stone) the height of your lawn, road base, gravel or whatever else meets your edge. This offers greater protection to the steel edge itself with less load bearing pressure felt and avoids creating a trip hazard too!

Be sure also to compact the drive and along the edge thoroughly before any traffic gets near your driveway edge to really sure things up.

Landscaping Edge

Can I use a Straightcurve for my driveway edge?

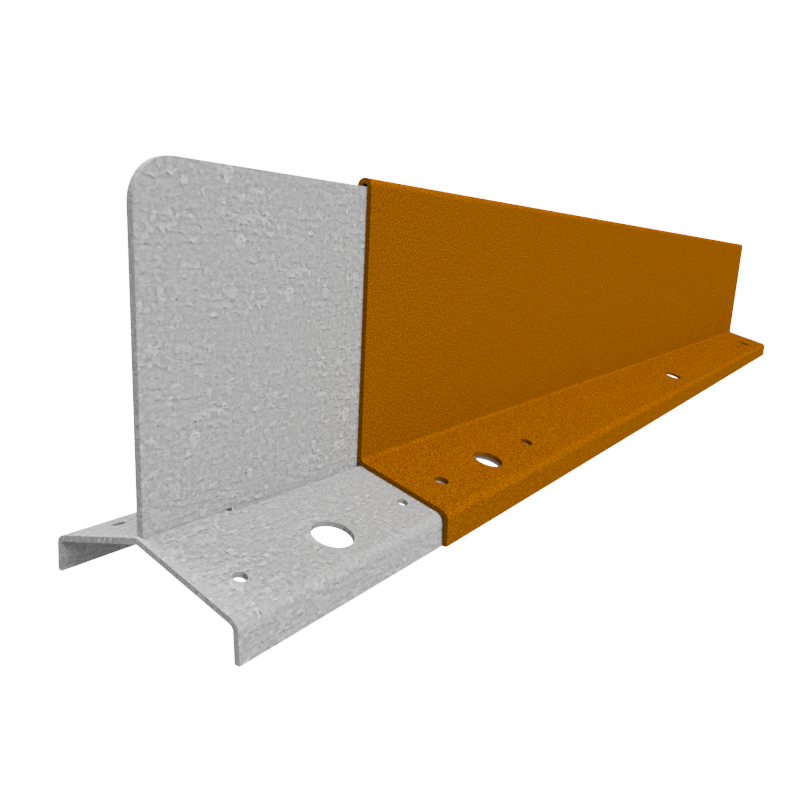

If your driveway is straight and you do not intend to drive over the edge, then yes you can use our Hardline landscaping edge with the grounding base. We recommend a concrete footing under each join and one in the middle of the edge. Make sure to insert the galvanized twisted nails in the edge while the concrete is still soft. Inserting the nails at an angle ensures a firmer hold. The edge is designed to hold gravel in and withstand occasional traffic driving straight over it if the top finishes flush with the surrounds.

Should you have a curved driveway edge that will not be driven on then our flexible lines can work fine. Driveways take a beating and are not that simple to edge off so the key is to allow atleast 70cm distance between the cartrack and the edge itself. With the finishing height set right you’ll find wheelbarrow or lawnmower traffic is fine, but keep the heavy vehicles off at all times!

So there you, go, I hope that information was helpful for you. If it was, be sure to watch out for other blogs from us!